- Home Page

- Company Profile

-

Our Products

- Aluminium Trihydrate

- Technical Grade Aluminum Trihydrate

- Cable Industry Aluminum Trihydrate

- SMC Aluminum Trihydrate

- Rubber Product Aluminum Trihydrate

- Water Treatment Chemicals Aluminium Trihydrate

- Highly Pure Alumina Trihydroxide

- Aluminium Trihydrate Powder

- White Aluminum Trihydrate

- Alumina Hydrate Powder

- Quality Approved Alumina Trihydrate

- Fire Retardant Alumina Trihydrate

- FRP ATH Powder

- ATH Flame Retardant Chemical

- Nalco Aluminium Trihydrate

- Industrial ATH Powder

- ATH Chemical

- Alumina Trihydrate Micronised

- Aluminium Trihydroxide Filler

- Aluminium Trihydrate For Cable Industry

- Aluminium Trihydrate For Rubber Products

- Nalco Alumina Trihydrate

- Aluminum Trihydrate suppliers

- Aluminium Trihydrate For Water Treatment

- Aluminium Trihydrate For Fire Retardant

- Aluminium Trihydrate For SMC And DMC

- Technical Grade Aluminium Trihydrate

- Aluminium Trihydrate In Glass

- Aluminium Trihydrate For Flame Retardant

- Technical Grade Aluminium Hydroxide

- 95 % Aluminium Trihydroxide Granules

- Hydrated Alumina powder

- Selenium Dioxide

- Synthesis Selenium Dioxide Sublimed

- Maruti Chemicals Technical Grade Selenium Dioxide Powder

- Selenium Oxide Powder

- Analytical Grade Selenium Dioxide

- Crystalline Selenium Dioxide Powder

- Electroplating Selenium Dioxide

- Reagent Grade Selenium Dioxide Powder

- Catalyst Selenium Dioxide

- Pharma Maruti Selenium Oxide

- High Quality Selenium Dioxide

- Selenium Dioxide Sublimed For Synthesis

- Selenium Dioxide suppliers

- Industrial Grade Selenium Dioxide Powder

- Selenium Dioxide For Electroplating Industry

- Crystalline Powder Selenium Dioxide

- Selenium Oxide supplier

- Reagent Grade Powder Selenium Dioxide

- Sodium Selenite

- Sodium Selenite Powder

- Sodium Selenite Chemical

- Animal Feed Sodium Selenite

- Poultry Feed Sodium Selenite

- Feed Grade Sodium Selenite

- Technical Grade Sodium Selenite Powder

- Analytical Grade Sodium Selenite Powder

- Sodium Selenite Anhydrous

- Sodium Selenite supplier

- Reagent Grade Sodium Selenite Powder

- Sodium Selenite 45 %

- Sodium Selenite For Animal And Poultry Feed

- Anti Oxidant Sodium Selenite

- Barium Carbonate

- Antimony Trioxide

- 5-Sulphoisophthalic Chemical

- Sodium Silico Fluoride

- Industrial Chemicals

- Dimethyl-5-Sulphoisophthalte Chemical

- Fluorspar Lumps

- Fluorspar Powder

- Isophthalic Acid

- Selenium Metal Powder

- Methyl 5-Acetyl Salicylate

- Aluminium Fluoride

- Fluoride Chemicals

- Aluminium Fluoride suppliers

- Sodium Silico Fluoride 99% 50 Kgs Bags

- Sodium Silico Fluoride 99% 25 Kgs Bags

- Sodium Silico Fluoride Manufacturer In Gujarat

- Sodium Silico Fluoride Supplier

- Sodium Silico Fluoride For Rubber Industry

- Technical Grade Sodium Silico Fluoride 99% Semi Crystal Industrial grade

- Sodium Silico Fluoride Manufacturer In India

- SSF powder suppliers

- Calcium Fluoride Powder

- ammonium silicofluoride suppliers

- 5 Sodiosulphoisophthalic Acid

- Dimethyl Sulfoisophthalic Acid Sodium Salt

- Aluminium Hydroxide

- Aluminum Fluoride And Chloride Powder

- Calcium Fluoride

- 5-Acetyl Methyl Salicylate

- Zinc Selenite

- Calcined Alumina

- Calcined Alumina Powder

- Chromium Oxide

- Aluminium Trihydrate

- Contact Us

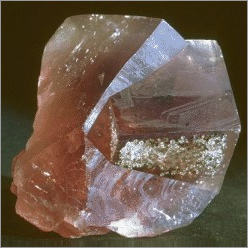

Solid Fluorspar Lumps

65 INR/Kilograms

Product Details:

- Purity(%) 85-95%

- Melting Point Approximately 1360C

- Application Metallurgical, Ceramic, and Chemical Industries

- Hardness (%) Mohs hardness 4

- Density 3.2 Gram per cubic centimeter(g/cm3)

- Surface Finish Rough, natural mineral surface

- Water Absorption Negligible

- Click to View more

X

Solid Fluorspar Lumps Price And Quantity

- 1000 Kilograms

- 65 INR/Kilograms

Solid Fluorspar Lumps Product Specifications

- Metallurgical, Ceramic, and Chemical Industries

- Approximately 1360C

- High structural strength

- 85-95%

- Mineral Lump

- Light gray to pale green

- Excellent at high temperatures

- 3.2 Gram per cubic centimeter(g/cm3)

- Mohs hardness 4

- Irregular Lumps

- CaF2: 85-96%, SiO2: <1.5%, Fe2O3: <1.0%

- Solid Lumps

- Rough, natural mineral surface

- Negligible

- 3.18

- Used as flux in steelmaking, aluminum production, glass, and ceramics

- Low

- Low

- Basic Refractory

Solid Fluorspar Lumps Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 100 Kilograms Per Week

- 1 Week

- Yes

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

Product Description

Driven by a vision to achieve growth in the chemical industry, we are engaged in manufacturing and supplying Solid Fluorspar Lumps. These are relatively low melting point halide minerals, used as flux to lower the melting point of raw materials in steel production. The lumps are obtained from the earth crush. The clients can avail our Solid Fluorspar Lumpsin bulk quantity at affordable prices. We deliver our products to the clients within the given time frame.

Specification

|

Calcium Fluoride |

90% min |

|

Silicon Dioxide |

8% max |

|

Size |

10-50 mm (90 % min) |

|

Form |

Solid |

|

Brand |

Maruti Chemicals |

|

Packaging Type |

PP Bag |

|

Packaging Size |

50 Kg |

Features:

- Composed of calcium fluoride

- Suitable for smelting process

- Effectively remove impurities

Further Details:

- Fluorspar is a halide mineral composed of calcium fluoride. Having a relatively low melting point, the mineral is extensively used as an important flux in smelting. Corresponding to different grades of purity, Fluorspar Lumps have various industrial uses. The lowest of the three available grades, Metallurgical grade fluorite, is used as a flux to lower the melting point of raw material in steel production for the removal of impurities.

- Maruti Chemicals Company offers Fluorspar Lumps, which it caters to the varied requirements of the large number of industries. These lumps can be availed from us in in specific particle size and purity as required.

APPLICATIONS:

- Ceramic Industry/ Glass Industry

- Steel Industry

- Metallurgy Industry

Structural Excellence and Chemical Purity

Solid Fluorspar Lumps are prized for their high CaF2 content (85-96%), superior structural strength, and stable performance at elevated temperatures. Their basic refractory nature and low thermal conductivity make them essential for demanding applications in metallurgy and ceramics, offering both reliability and longevity.

Versatile Applications Across Industries

These lumps serve as a flux in steelmaking and aluminum production, facilitating impurity removal and enhancing product quality. Their use extends to glass and ceramic manufacturing, where their chemical stability and negligible water absorption contribute to improved processes and finished products.

Convenient Packaging and Safe Handling

Solid Fluorspar Lumps are supplied loose in bulk or securely packed in 1-ton jumbo bags. Odorless and non-toxic under normal conditions, they are safe for handling, storage, and transport. Proper storage in dry, covered areas ensures unlimited shelf life and preserves mineral properties.

FAQs of Solid Fluorspar Lumps:

Q: How should Solid Fluorspar Lumps be stored to maintain their quality?

A: Solid Fluorspar Lumps must be kept in a dry, covered storage area to protect against moisture and environmental contamination, ensuring their unlimited shelf life and preserving their physical and chemical properties.Q: What are the main industrial uses for Solid Fluorspar Lumps?

A: These lumps are primarily used as a flux in steelmaking and aluminum production, and are also important in glass and ceramic industries due to their high purity, chemical stability, and structural strength.Q: When is the optimal time to use Solid Fluorspar Lumps in metallurgical processes?

A: Solid Fluorspar Lumps are typically introduced during the melting or refining stages, where they help lower melting points, assist in impurity removal, and improve metallurgical yields.Q: Where are Solid Fluorspar Lumps commonly exported or supplied from in India?

A: In India, Solid Fluorspar Lumps are supplied and exported by various manufacturers, traders, and importers, ensuring reliable availability for domestic and international buyers.Q: What process benefits do Solid Fluorspar Lumps provide in ceramic and glass manufacturing?

A: Their low porosity and chemical composition enhance vitrification and clarity, reduce energy consumption, and contribute to strong and stable finished products in ceramic and glass production.Q: What specific advantages do Solid Fluorspar Lumps offer over other flux materials?

A: They deliver excellent dimensional stability at high temperatures, low water absorption, unmatched purity, and high structural strength, facilitating consistent results in metallurgical and ceramic applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send SMS

Send SMS